The Development of Stone as a Construction Material

From the sarsen stones of Stonehenge to the marble and sandstone of the Taj Mahal, stone has graced historical buildings for centuries, demonstrating its longstanding historical and cultural significance as a construction material. Construction methods have evolved significantly since these monumental structures were erected, transitioning from skilled craftsmanship to modern techniques that prioritise efficiency and precision. Today, façades can be economically engineered using stone cladding, preserving the aesthetic of traditional robust stone construction while meeting contemporary demands.

In Edinburgh, stone has been a key component of façades and structures for centuries due to its suitability for the local climate. Typically, stone is a heavy, durable material capable of withstanding significant weight, making it ideal as both a load-bearing structure and a thermal mass. While traditional methods are still employed, particularly for cultural and historical buildings, increasing commercial demand has driven innovations in stone construction. The introduction of iron skeleton frameworks revolutionised public construction, enabling new structural approaches and paving the way for stone cladding. Cladding, often cut into shapes that imitate authentic stone frames, is affixed to an underlying structural layer, providing both functionality and aesthetics.

Different types of joints serve various purposes in cladding systems. Open joints allow for weathering and general repairs, while adjustments to the planes can be made via the fixing and cavity. Anchorage and support framing are critical due to stone's susceptibility to stress concentrations from one-way bending. Linear anchorage using kerf bars is an effective safety measure, as it minimises the risk of failure. By supporting only the corners, this method ensures that any failure does not result in the release of the panel. Instead, reactions are transferred along the length of the kerf bar, keeping the stone intact.

Close scrutiny during the manufacturing stage of cladding systems is essential due to past defects in installation and fixation. For instance, marble panels less than 50 mm thick have been prone to bowing [1], as seen in Alvar Aalto’s Finlandia House in Helsinki [2]. This failure is often attributed to factors such as the panel's weight, material distortion from "creep" [3], moisture, thermal cycles, and atmospheric exposure. In response to such failures, composite cladding has emerged as an alternative, a development was long-anticipated in the construction industry. Options include concrete-backed panels, aluminium honeycomb panels, and resin-backed panels, among others.

Image 1: Alvar Aalto’s Finlandia House in Helsinki. Photo by University of Helsinki

Errors in cladding systems can also be minimised by addressing factors such as temperature differentials between exterior and interior surfaces, relative expansion coefficients of stone and concrete, reinforcement within concrete panels, rigidity of the stone-to-concrete connection, and concrete shrinkage [1]. Aluminium honeycomb-backed cladding represents a recent advancement in stone veneer technology, naturally evolving from composite panels. Its unique honeycomb structure reduces the cladding’s weight by up to 80% compared to solid stone, while maintaining strength and durability. Prefabricated systems enhance buildability, and impervious layers provide waterproofing. This innovation offers additional benefits, such as improved impact resistance and high bending strength. A notable example of its resilience is the Atlantis Resort in the Bahamas, where aluminium honeycomb panels have withstood five hurricanes without damage [4]. Similarly, resin- or polymer-backed cladding uses ultra-thin stone veneers (3–10 mm) attached to a polymer layer. Despite their lightweight nature, these panels are 2–3 times stronger than conventional stone panelling.

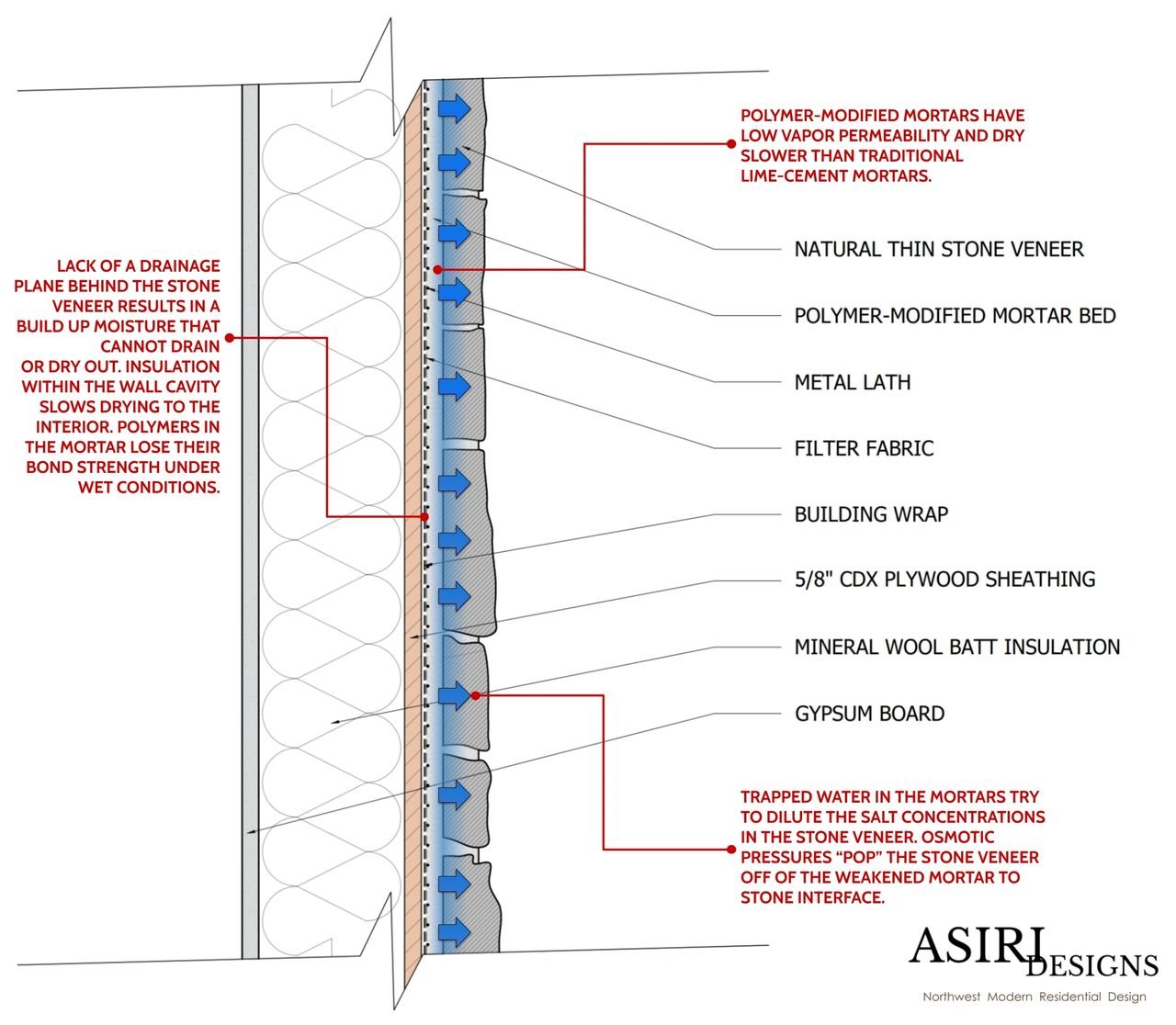

It is important to note, however, that this strength test is done at the begining of the system’s life and does not account for any reduction in strength of the resin over time. Moisture infiltration into the stone or resin layer can cause delamination, cracking, or spalling, especially in environments where the cladding will be subject to freeze/thaw action. Additionally, resin-backed systems are suceptible to degredation upon prolonged exposure to UV light, repeated thermal expansion and contraction can weaken the bond between the resin and stone veneer, and may react to atmospheric chemicals, compromising the long-term structural integrity. These vulnerabilities highlight the importance of careful material selection and proper installation, especially in harsh climates or environments.

Image 2: Issues with polymer-backed cladding examples. Credit: Asiri Designs

Environmental impact is another consideration. Prefabricated systems often incorporate synthetic materials like polymers and aluminium, which can have a higher carbon footprint during production compared to locally sourced stone. Additionally, the increased reliance on prefabrication and mechanisation comes at the cost of traditional craftsmanship quality, often resulting in a lower level of educational training for workers. Lightweight cladding systems, while efficient, may also have structural vulnerabilities. In regions prone to natural disasters such as earthquakes, some cladding systems may not perform as robustly as solid masonry. Furthermore, their reduced thermal mass compared to traditional stone construction may lead to higher energy demands for heating and cooling.

Minimising the risk of failure involves reducing the probability and mitigating the consequences of potential issues. While it is impossible to eliminate all uncertainties, engineers and architects must balance quality and expected exposures to achieve a robust and practical design. With ongoing advancements in stone cladding technology, its numerous benefits continue to make it a popular choice in modern construction. Prefabricated panels significantly accelerate construction timelines, reduce environmental impact by using less stone, and lower costs for clients, all while retaining the timeless appeal of traditional stone construction. However, it is crucial to weigh these benefits against potential limitations to ensure that cladding solutions are both practical and sustainable in the long term.

References;

[1] Yates, T.J.S., Chakrabarti, B. and Ashall, G., 2001. Lightweight veneer stone cladding panels. BRE Centre for Whole Life Construction and Conservation.

[2] Bouineau, A. and Perrier, R., 1995. La décohésion granulaire, maladie des revêtements de façade en marbre. Pierre Dimensionnelle, August.

[3] Yates, T.J.S. and Chakrabarti, B., 1997. External cladding using thin stone. BRE Centre for Whole Life Construction and Conservation, p. 2.

[4] Feller, R.M., 2017. Stone veneer panels on aluminium honeycomb combine the beauty of natural stone with the design freedom, strength, and lightness of metal panels. Architectural Record.

[5] Lewis, M.D., 1995. Modern stone cladding: design and installation of exterior dimension stone systems. ASTM, p. 29.

[6] CWCT, 2021. Bonded Brick Slip Systems. [online] Available at: https://www.cwct.co.uk/blogs/health-safety/bonded-brick-slip-systems [Accessed 16 January 2025].